In our Tools of the Trade series, James Cartwright explores the devices that, from humble beginnings, have gone on to change the course of creative scenes. From the Risograph’s imperfect charm to the defect machine that inspired the evolution of hip-hop, discover the tools whose legacies continue to define the way we work.

Illustrations by Pete Sharp.

When you ask Riso Kagaku, the Japanese company behind the now massively popular printer Risograph, what their mission is, they’ll tell you they “focus on making a difference in how your office functions with our state-of-the-art products.” But, while Riso Kagaku translates to “ideal science,” it is not the story Risograph users tell.

“It’s an emotional rollercoaster; it’s such a pain in the ass!” LA-based publisher and Riso specialist Clay Hickson says of the esoteric printing process. “Coming from a printmaking background, the thing that they always drill into you is consistency. If you're going to make an edition of prints, they’ve got to be consistent, and this is like the least consistent printing method there is.

“The whole time I'm printing I'm just losing my mind. Every little smudge, every little mark, every misprint, you just think, this is a disaster, these are going to look horrible. And then, somehow, at the end you put it together and all those things don't really matter and it looks okay.”

The Risograph to which Clay is referring is not one of many all-singing, all-dancing laserjet systems manufactured by Riso in recent years, but a 20-year old stencil duplicator around which he has built an entire business. Clay publishes art books and illustration monographs under the name Tan ’n’ Loose Press, as well as a monthly Riso-printed political periodical called The Smudge.

The Risograph is a machine much like a photocopier, but which functions more like a mechanical screen printing bed. The earliest models were produced in the early 1980s, with the first fully-automated version (the dangerous sounding Risograph 007) appearing in 1984.

Coming from a printmaking background, the thing that they always drill into you is consistency.

Before the arrival of the 007, the Risograph was even more of a pig to use than Clay’s daunting description – users would reach into the machine and attach their own stencils to the printing drum – but this new model exposed the master, fixed it to the print drum, and transferred the design to paper all within the clinical confines of a white plastic shell. That ease of use changed the face of low-cost printing for good.

But not immediately. For about 20 years the Risograph languished in church halls, school staff rooms and the offices of local political parties, serving as a workhorse for those in need of low-budget, last-minute printed matter.

Once exposed, a Risograph master screen is capable of printing up to 8,000 copies, meaning that huge editions can be produced with minimal setup costs. Political parties in particular were enamoured by this cheapness and loved the Riso for its easy access to specific spot colors; most would print in black, accented with their official party color. But after years of use and abuse as a vehicle for political missives, the Risograph finally found its spiritual home with a more creative crowd.

As the Risograph slowly permeated the consciousness of artists, designers and illustrators the world over, it fast became one of their favorite printing tools. By the late 2000s, things were really picking up for the Riso. “There was a great piece on Rollo Press in the Japanese magazine Idea,” says Ken Kirton, founder of Hato Press, a Risograph print studio and publisher in London.

“It was just a one-page interview with a photo of a printer in a living room and all the pages from a zine or a book laid out. That had a large impact on me and Jackson (Lamb, his Hato Press co-founder) and we realized we could actually set up a publishing house and work with different people through this tool.”

Through the Riso, Ken and his team were able to work with their heroes early on in their careers, taking on clients like the Serpentine Gallery and the British Council, and collaborating with designers like Martino Gamper and Michael Marriott. Of course, much of that was to do with their skill as designers, but they believe the lure of the Riso had a big impact too.

“At that time in the design community, there was a rumor that there was this printer that had super nice color aesthetics that would print on quality paper. The fact that we had one meant we got to work on some really fascinating projects.”

The fact that we had one meant we got to work on some really fascinating projects.

Clay concurs that owning a Risograph opens up all sorts of potential for collaboration, but even better, enables artists and designers with limited means to produce all kinds of printed matter from scratch.

“We have it all set up here, and we just go down to the garage and we can make a book,” he says. “That’s special, just having the power to produce something. With The Smudge, we get all the content, lay it out, and that’s about two days work, and then as soon as it's done I just go downstairs and print it. It’s so immediate and efficient in that way.”

It’s maybe no surprise that the qualities that made the Riso appealing to political parties are also advantageous to cash-strapped creatives. Equally, organizing around a press appeals to designers and printers with a social agenda, too. Hato values its printing capabilities for their potential to foster strong communities, either through teaching people the print process or simply inviting collaborators into their space to use the Riso. “We see that very much as a service supporting our community,” Ken says.

Mark Pawson discovered the Riso in 1992 in the basement of Knust Extrapool, a Dutch gallery and print shop that houses an abundance of printing machinery. For all the positivity, Mark expresses some frustrations with the ubiquity of Riso.

“There’s a vogue and a trend for people doing ten dollar Riso prints, some of which are a bit crappy and have track marks down them. When I see those I just suck my teeth, walk past and don’t say anything, but it’s a bit lazy. If I was in lecturer mode I would hand those prints back to them with a rubber and say, go and rub off those roller marks and bring your work back to me.”

As a counterpoint to cheap prints, a new wave of high-end fine art Risograph print houses have emerged producing meticulous editions that push the medium to its very limit. Inspired by those early experiments at Knust Extrapool and boosted by innovations from Landfill Editions, enterprises like Viktor Hachmang and Julian Sirre’s Vinex Pers have cast off the Risograph’s reputation for being a low-budget process by releasing limited edition multi-layer prints by some of Europe’s leading artists. “It’s an interesting development that I wouldn’t have expected,” Mark says.

It’s not just through printing that creatives are using Riso to innovate either. “In Philadelphia there’s this Riso shop called Risolve and they build insane contraptions to go with their machines,” Clay says. “They have a drum washing booth that gets those things spotless! He’s also got a conveyor belt for drying the prints as they come out of the machine.”

The track marks, the misprints, the strange blending of inks, all contribute a unique patina to the image.

But perhaps we’re getting ahead of ourselves with the frills of elite Riso printing. Back to the basics – just how exactly do you print with this thing?

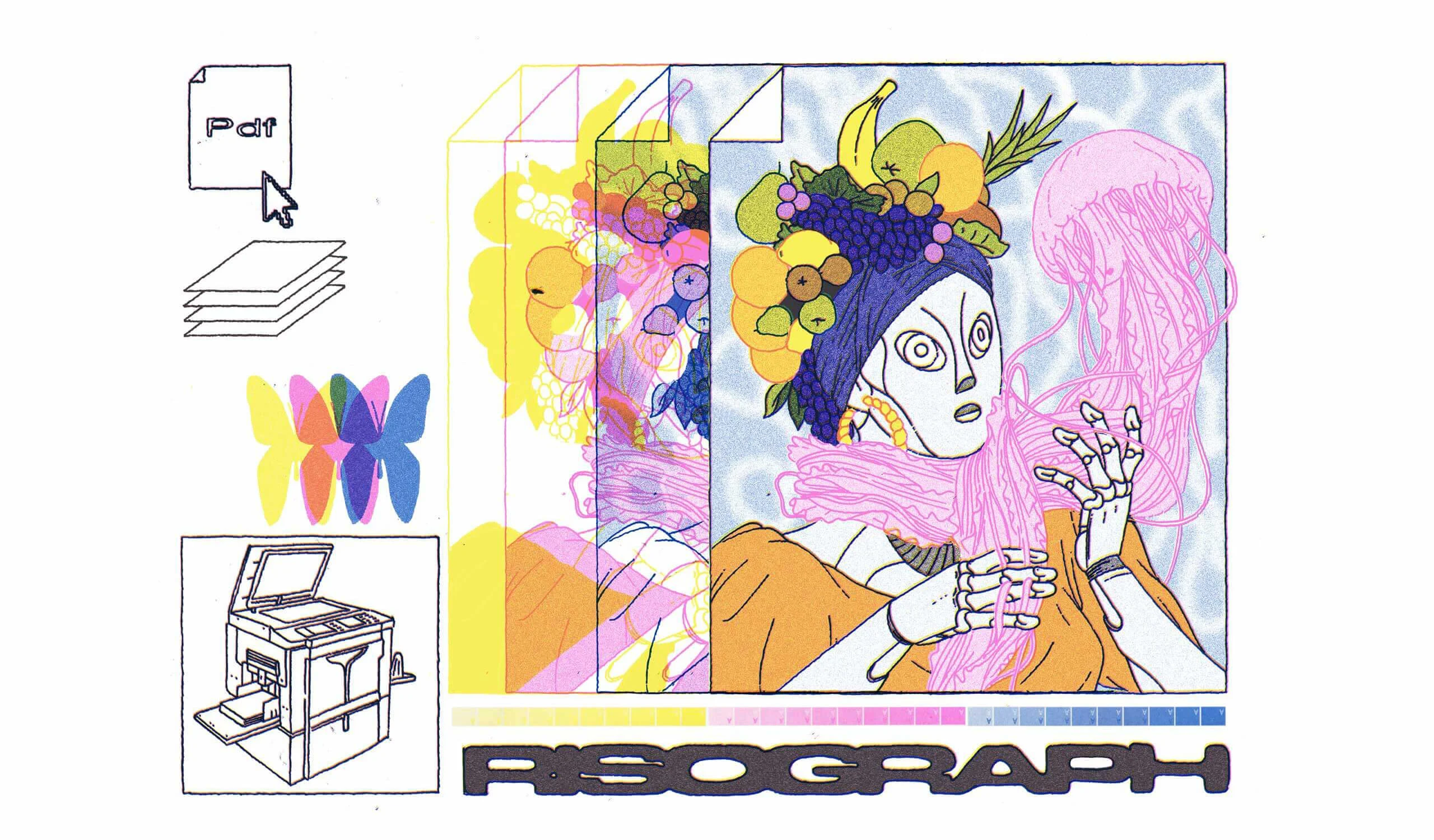

The Risograph can create a master direct from a digital file or from a physical piece of original work exposed on a glass scanning bed. Artwork is sent to a thermal print head which burns through a polyethylene and hemp master screen perforated with a fine dot mesh. The master is cut and automatically transferred onto the print drum containing the printing ink—each color requires its own drum—then the ink is pulled up into the hemp layer of the master and squeezed through the mesh.

As the drum rotates the paper stock passes through the body of the machine for printing before being fired out the other side into a small rack. As with screen printing, the perforations in the screen allow ink to pass through the mesh and transfer the image to paper. This process can be repeated for as many layers as your artwork allows with as many colors as Riso Kagaku can offer.

Once again, Clay is keen to stress that this whole process is not without pitfalls. “You have to sort of hack the machines. I remember early on there would be times when I'd be printing a poster for someone that was a full sheet of solid color, so the paper would wrap around the drum and get jammed because there was so much ink on it. So I would have to hit the button, and quickly run round to where the paper would come out and jam a coat hanger deep into the machine so that it would catch the paper before it could wrap up.

“Now I just tell people you can’t have that much ink coverage.”

In most cases, it’s the huge margin for error that has attracted artists to the Riso, its imperfect results adding a sort of human charm to the medium. The track marks, the misprints, the strange blending of inks, all contribute a unique patina to the image that would be eliminated in a more precise process.

“It appeals to this notion that people want to find things that are more bespoke, more human, or more crafted,” Ken says .

But before you rush out to lay claim to one of these machines yourself, a word of warning; none of our Riso wizards can boast of a sizeable income from their print work. “The press was never really set up to make money,” Ken admits. “It existed just to cover the costs of the studio space.

“Yeah, every time people come over to where we live in my aunt's beautiful house in Hollywood, we always joke, ah, the house that zines built!” Clay says. “And then we're like, “Haha, no, we don't own this house.”